This oven allows you to cook your bakery and pastry products. This gas or oil oven system allows you to reduce your energy bills and save space thanks to its 3 sides.

Ergonomics and userfriendliness

– Ergonomic handle with hub cap

– Magnet integrated on each side for blades of scarification

– Steam recall button on each side

Quality finishing

– Robust and careful finishing

– Brushed stainless steel facade

– No recesses difficult to clean

– Smooth surfaces with few asperities

Annular tubes steam ovens

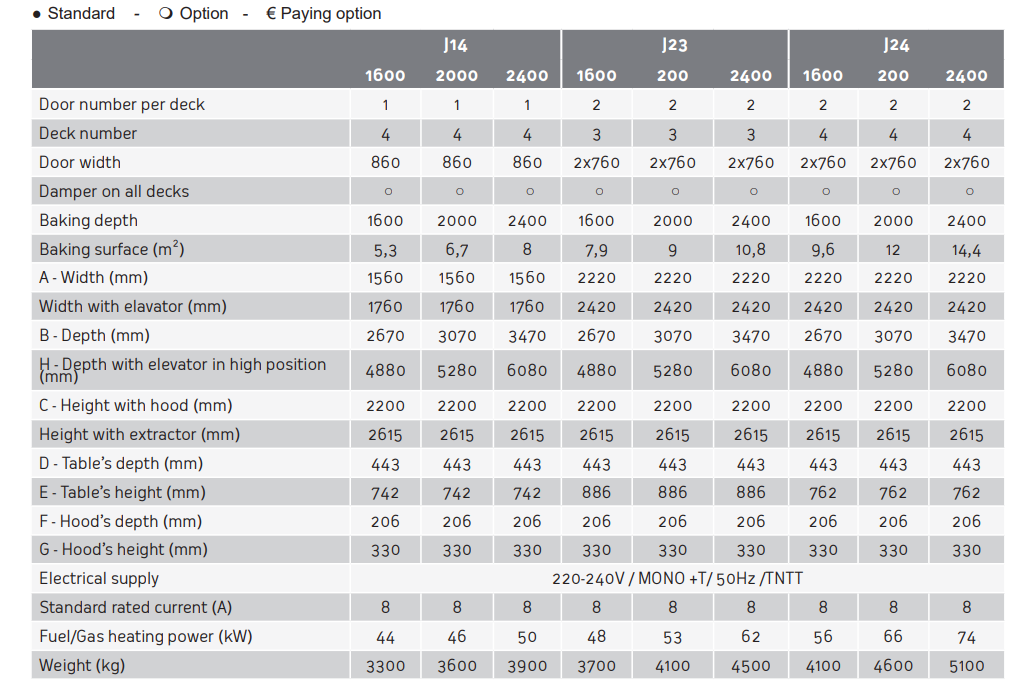

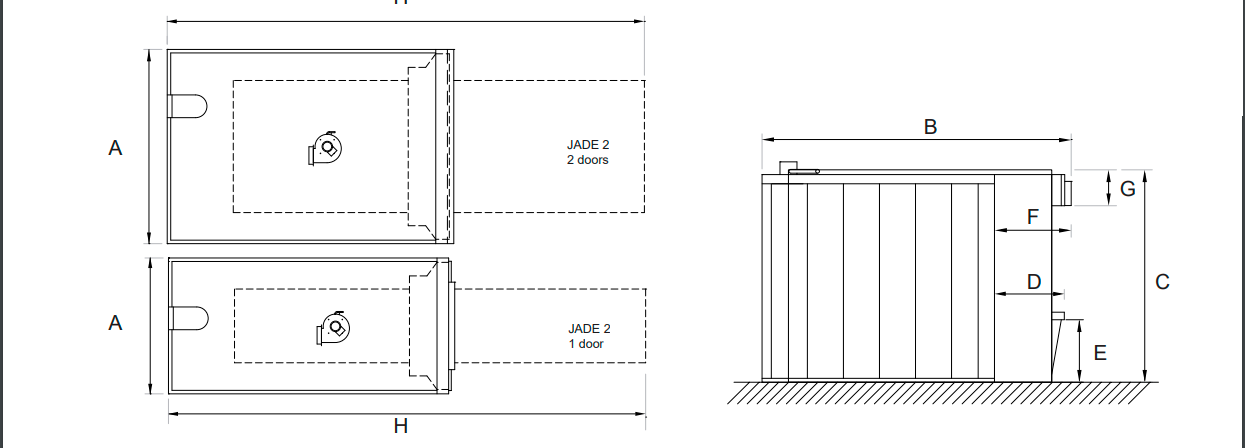

3 models are available :

J14 : 1 door per level / 4 levels

J23 : 2 doors per level / 3 levels

J24 : 2 doors per level / 4 levels

Available in natural gas, propane and heating oil version.

Jade Style range

Jade Style ovens are designed for baking and pastry-making applications, to the exclusion of any other type of use.

The burner is accessible on the left side of the front and a fan is placed on the front part, forcing the return of the burnt gases.

Slot-in on 3 sides, to optimize the working space in the bakery.

Construction

Thermal insulation is ensured by rockwool panels from 100 to 150mm of width depending on the walls, for an improved safety and an optimal energetic productivity.

The airtightness is guaranteed by fiber braids. The seals betweens the doors are made of metal.

A low voltage halogen lamp, of high intensity, ensures a perfect visibility of the products during the baking.

A tempered glass porthole protects every lamp from the effets of the heat.

The « Style » design

In line with the rest of the range, the hood retains the « Style » red and white design; without folds to avoid the accumulation of dust

New timers

4 seperate timers for each level to ensure a better visibility of the baking

Avantages

– Efficient steam generator on each level.

– Very good insulation of the oven, on the outside as well as between the chambers, which limits heat losses and allows energy savings.

– Facade entirely made of brushed stainless steel.

– The seals of the window panes are protected on each level.

– Control panel and handles on the right or the left.

– Fuel or gas burner

– For your safety, each vapor tube is tried and tested at high pressure in the factory, before being dispatched.

An optimal heat exchange

The refractory stainless steel furnace ensures a perfect heating exchange between the annular tubes and the heating areas.

The device for recycling hot gases, placed in front of each baking area, allows a better thermal exchange and improves the energetic performance.

It also contributes to the excellent homogeneity, in all the baking areas.

The rotation of the recycling turbine is assured by a remote-fixation motor, equiped with a dissipation fan and an isothermal protection.

Technical features